(1) Trace moisture -ASTM D1533

The level of moisture will cause abnormal fluctuations in the insulation performance of the oil, which is one of the important factors affecting the dielectric strength of the oil and the service life of the transformer。

(2) Acid value - ASTM D974

During long-term operation, the transformer oil gradually produces acidic oxides and sludge and other degraded substances due to oxidation, which increases the acid value of the oil and affects the insulation performance of the transformer oil。

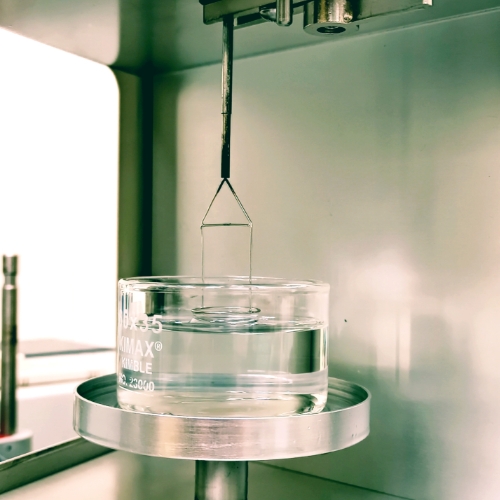

(3) Interfacial tension - ASTM D971

The presence of polar dissolved pollutants (acidic oxides and sludge) in transformer oil will reduce the interfacial tension and affect the quality of the oil. It is one of the important indicators for judging the degree of oil deterioration and polar pollution.。

(4) breakdown voltage - IEC 60156

This method uses spherical electrodes. The moisture, acid value and impurities of the oil will affect the strength of the dielectric. This item is an important indicator for judging whether the oil is subjected to electrical stress.。

(5) Color- ASTM D1500

Preliminary inspection of the color and deposits in the oil。